Highly precise cutting improves material efficiency and enables automatic welding.

mbs has developed a new generation of orbital saws for tubes and pipes that ensure highly precise cuts, small cutting gaps and minimum blade costs. The first of these machines was recently put into operation at a filtration pipe manufacturer“s site.

mbs has successfully completed the turnkey supply of its first new-generation MM orbital saws for automatic thin-walled pipe cutting. The integrated solution comprises an inclined pipe feeding device, the sawing unit, which rotates around the central pipe axis, and the discharge of the cut pipe sections up to the point where they are picked up by a robot.

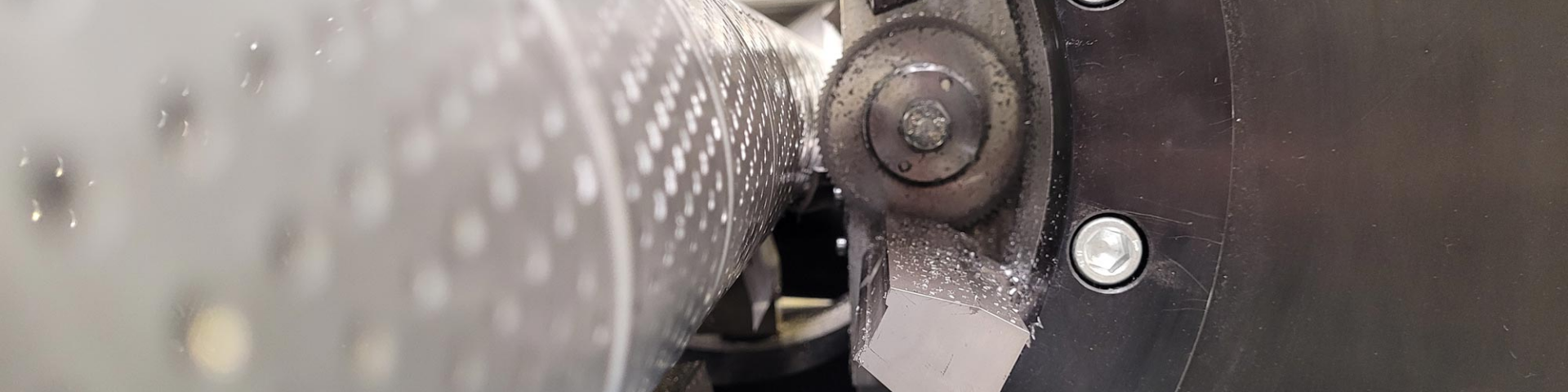

In contrast to conventional circular saws, orbital cutters use two small, thin blades arranged opposite from each other. They operate with a very small sinking depth into the pipe cross-section. This results in high material efficiency and, due to the exact blade guiding, in a much more precise cut. What is more, the orbital blades cost just about 20 percent of what circular saw blades cost.

The ball bearing spindle of the machine operates with a positioning accuracy of +/- 0.07 mm. This ensures that the saw is also suitable for cutting pipes into sections intended for automatic welding onto flanges and required to comply with extremely tight cutting gap tolerances. A further important benefit of orbital saws is that they do not affect the roundness of the pipes, even if the pipe walls are as thin as just 0.7 mm. This is possible thanks to the high precision with which the pipes are clamped and to the small blade diameter.

According to Marc Hoffmann, Managing Director of mbs GmbH, orbital cutters provide a number of benefits compared to circular saws: „To cut a 170-mm-diameter pipe featuring a 3.2 mm thick wall with a circular saw, I would need a 580-mm-diameter blade costing around 500 euros. In contrast, our new orbital cutters use two 1.6 mm thin blades of only 80 mm diameter that cost less than 30 euros each. These blades achieve a much more accurate cut and, as a result, much smoother cut faces.“

With a view to the relative loss of material, the shorter the sections into which a pipe is cut, the more important the blade thickness becomes. Consequently, particularly high cost savings are achieved when cutting pipes into narrow rings.

The first of mbs“ new-generation orbital cutters is in operation at a filtration systems manufacturer. Featuring efficient automation and precise servo technology, the machine about every 50 seconds.

About mbs

Marc Hoffmann founded mbs GmbH in 2010 with the objective to manufacture customized machinery and plants for industrial production. Since then, the company has focused its activities on sawing and cutting machinery with a wide range of peripheral facilities such as feeding, weighing, blanking, punching and beveling equipment as well as process control and robotics.

Special machinery, such as flying shears, for turnkey supplies is manufactured at the mbs production site in the German town of Alsdorf, located in the technology region of Aachen.

Since 2014, mbs has been cooperating with Tsune Seiki Co., Ltd. Under this cooperation, mbs adapts sawing und cutting machines made by the Japanese company to the requirements of European customers.

Company-Contact

mbs

Marc Hoffmann

Konrad-Zuse-Straße 32

52477 Alsdorf, Germany

Phone: +49 2404 95849-10

E-Mail:

Url: http://www.mbs-ac.de

Press

VIP Kommunikation

Regina Reinhardt

Dennewartstraße 25-27

52068 Aachen

Phone: +49 241 89468-24

E-Mail:

Url: http://www.vip-kommunikation.de

Die Bildrechte liegen bei dem Verfasser der Mitteilung.