The demand for new coating solutions for oversize boards in the industry is growing.

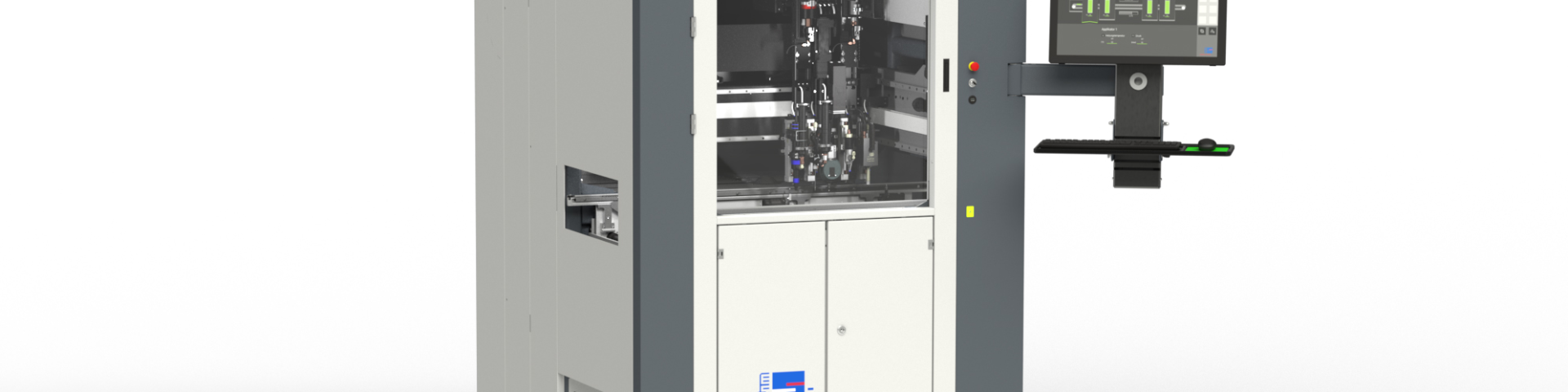

The ProtectoXP and ProtectoXC dispensing and coating systems from Rehm Thermal Systems protect electronic assemblies against harmful environmental factors such as moisture, corrosion, chemicals, dust and vibration. As these assemblies are becoming ever larger in high-voltage power electronics – especially in the fields of 5G technology, e-mobility and renewable energy – the demand for new coating solutions for oversize boards in the industry is growing. The systems of the Blaubeuren-based manufacturer meet this requirement with widths up to 508 mm and lengths up to 640 mm already covered by its basic configuration. Optional adaptations to software and hardware also allow for customised, fully automated processing of extreme sizes.

As the complexity of electronic systems increases, so too does the number of logic assemblies which, in conjunction with power modules, have to be integrated into a circuit board. Ever larger boards are the consequence. Oversize board options for the dispensing and coating systems of the Protecto series from Rehm facilitate reliable coating of large circuit boards of this sort.

From standard features to the oversize board

Even with the standard features of the Protecto systems, circuit boards up to a maximum width of 508 mm and a length of 640 mm can be processed. While the largest processing area is reserved for the external applicator, up to three following applicators, which, although they move shorter distances, cover a not inconsiderable minimum dispensing area of 400 mm x 508 mm even when fully equipped. For special applications with even larger circuit boards, Rehm Thermal Systems offers its own customised solutions. It is not only possible to extend the processing range of all the applicators through the software – the infeed and outfeed of the systems can also be increased to virtually any length using a rucksack construction which makes it possible to hold significantly larger circuit boards. The precise configuration of the possible working areas is coordinated with the customer and is based on their specific requirements profile.

A growing market: oversize circuit boards

Oversize circuit boards are used in a multitude of applications and areas. In lighting technology, for example, LED segments with a length of up to 1.5 m are used, which could not be coated automatically without an oversize board option of the sort Rehm offers with its Protecto series. The same applies to the area of solar inverters and to processing special foils in battery production. The 5G industry, power modules for windmills and charging stations on garage forecourts also depend on oversize circuit boards. With automatic processing of these assemblies within an enclosed system, Rehm Thermal Systems offers a practical advantage for producers and suppliers.

The right system for every application: Protecto conformal coating

The Protecto series from Rehm Thermal Systems delivers reliable, automated processes and precise results for the application of a wide range of materials. Up to four applicators that can be operated simultaneously offer users a variety of options: along with dispensing, these include the possibility of creating freely definable, three-dimensional housing shapes by simple application, immediate curing of UV paints and casting and gluing various materials.

As a specialist in the field of thermal system solutions for the electronics and photovoltaics industries, Rehm is a technology and innovation leader in the modern and economical production of electronic modules. As a globally operating manufacturer of reflow soldering systems with convection, condensation or vacuum, drying and coating systems, functional test systems, equipment for the metallisation of solar cells as well as numerous customer-specific special systems, we are represented in all relevant growth markets and, as a partner with more than 30 years of industry experience, we implement innovative manufacturing solutions that set standards.

Company-Contact

Rehm Thermal Systems GmbH

Frank Wagner

Leinenstraße 7

89143 Blaubeuren

Phone: 07344 9606 746

Fax: 07344 9606 525

E-Mail: f.wagner@rehm-group.com

Url: http://www.rehm-group.com

Press

Rehm Thermal Systems GmbH

Carmen Hilsenbeck

Leinenstraße 7

89143 Blaubeuren

Phone: 07344 9606 535

Fax: 07344 9606 525

E-Mail: c.hilsenbeck@rehm-group.com

Url: http://www.rehm-group.com

Die Bildrechte liegen bei dem Verfasser der Mitteilung.